Project Overview

The Salmon Creek Wastewater Treatment Plant (SCTP) receives and treats roughly 8–10 million gallons of wastewater per day from approximately 120,000 Clark County homes and businesses. The Phase 5 Expansion program is a planned investment which builds on four previous expansions over the past 40 years. The Phase 5 Expansion projects will continue through 2024. The Phase 5 Expansion projects will ensure that the treatment plant can continue to meet the region’s long-term wastewater treatment needs and continue safeguarding public health, environmental quality and our community’s economic future. Once complete, the Phase 5 Expansion projects will allow for future decommissioning of Ridgefield’s aging wastewater treatment plant and outfall into Lake River (after other projects are also completed within the local collections systems).

Phase 5 Expansion projects include: Columbia River Outfall, Columbia River Effluent Pipeline, Secondary Treatment Process Improvements, and Odor Control and Existing Facilities Improvements (completed in Fall 2021).

Interactive Map

Use the interactive map below to learn more about each project and the potential impacts related to construction.

Columbia River Outfall and Effluent Pipeline

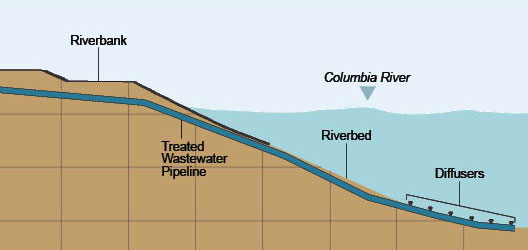

The Salmon Creek Wastewater Treatment Plant (SCTP) treats wastewater from approximately 120,000 Clark County residents. Treated water, or effluent, is conveyed through a 30-inch pipeline built in 1974 and discharged into the Columbia River via a submerged outfall diffuser. The Columbia River Outfall and Effluent Pipeline project will plan, design and build a larger effluent pipeline and an improved outfall diffuser.

The new 48″ diameter pipeline and new outfall diffuser are needed to replace the existing aging effluent pipeline and outfall, and for future increased plant capacity to support planned growth in the community. The new outfall diffuser will improve mixing and dilution of treated water discharged into the Columbia River. The project will also reduce ongoing maintenance at the discharge location and allow future decommissioning of Ridgefield’s aging wastewater treatment plant.

Project Design and Pipeline Route

The first task of this project was to determine the preliminary design and preferred route for the new conveyance pipeline. This step in the process has been in discussion for over a decade and is now complete. All necessary permits and easements have also been obtained. The route of the replacement pipeline is parallel to the existing effluent pipeline. The route will cross private property, the Burlington Northern Santa Fe Railway, existing utility lines, Salmon Creek, Lake River, and two road rights of way.

Improved Outfall Diffuser for Water Quality

As part of our goal of fostering a healthy environment, an improved river discharge assembly, called an outfall diffuser, will be built at the end of the new effluent transmission pipeline. The outfall diffuser will improve Columbia River water quality by better diluting and mixing discharged treated water. Since the Department of Ecology (Ecology) monitors and regulates the health of the Columbia River, we’ve worked closely with Ecology to determine the best location and design for the outfall (discharge location). The mixing zone will meet stringent standards set by Ecology to ensure clean water for swimming, boating, fishing, and aquatic resources.

An improved outfall diffuser will ensure that discharge of treated water is mixed and diluted efficiently and will meet water quality standards.

Project Documents

See project documents on the Documents & Links page.

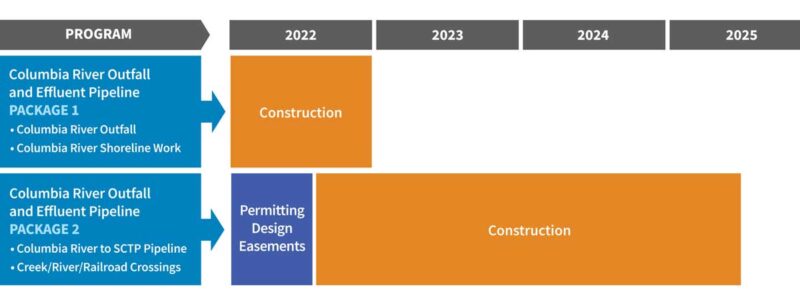

Schedule

- Learn more in the project fact sheet (PDF)

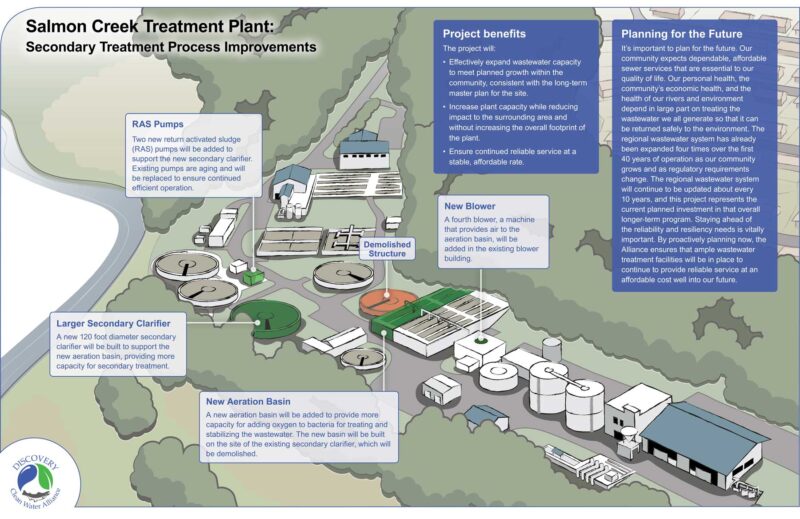

Secondary Treatment Process Improvements

As part of the Salmon Creek Treatment Plant Phase 5 projects, the Alliance will expand the biological treatment process to increase the plant’s treatment capacity from approximately 15 million gallons per day to 17.5 million gallons per day within the existing facility footprint. This will be accomplished by constructing a new Aeration Basin and Secondary Clarifier in the middle portion of the plant and an older structure will need to be demolished to make space for these new facilities. In addition to these new structures, improvements to several mechanical pumping and air supply systems will be made inside existing buildings.

Schedule

Construction is slated to begin in 2022 and be completed by mid-2025.

- Learn more in the project fact sheet (PDF)

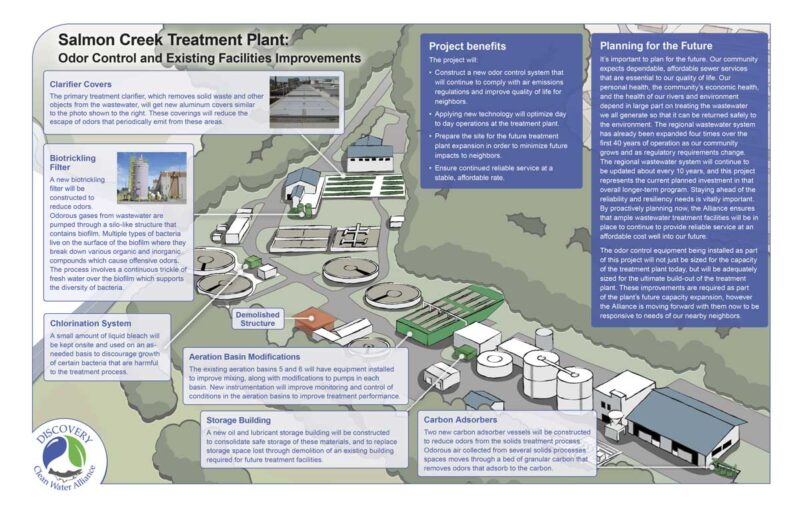

Salmon Creek Treatment Plant Odor Control and Existing Facilities Improvements

Although our operators have always taken great care in minimizing odors by keeping the treatment processes balanced and operating in a healthy manner, some odors do occur as a result of regular operations. We undertook this improvement project to eliminate about 80-90% of the odors nearby neighbors may have experienced before the project was completed.

As part of this project, we installed new odor control systems at the front and back ends of the plant. On the front end, new biotrickling filters were installed to treat air from the preliminary treatment and primary treatment processes. In order to help collect the air for treatment, new aluminum covers were added over the Primary Clarifiers. On the back end, new carbon adsorbers now treat air collected from the solids treatment process. These methods have proven very effective in reducing odors and the technologies were selected to specifically treat odors generated at each end of the facility.

The new equipment was installed in 2021 and now captures and treats the odor that is generated as a result of regular treatment operations; however, some odor generating events that result in one-off odor releases may still occur from time to time, such as when treatment processes are taken off-line for cleaning and repair.

Schedule

Construction began in 2020 and was completed in the fall of 2021.

- Learn more in the project fact sheet (PDF)

Columbia River Water Quality Monitoring Program

In an effort to provide Washington State with an accurate Water Quality Assessment, the Discovery Clean Water Alliance and City of Vancouver worked together to support Ecology’s Water Quality Assessment (required by the Environmental Protection Agency under the Clean Water Act) by providing:

- A thorough, technical review of the past volunteer sampling program by qualified water quality scientists. Findings of this review were provided to Ecology in October 2018.

- A two-year monitoring program designed to provide definitive, scientifically-defensible data to accurately assess and measure dissolved oxygen (DO) levels in the Columbia River between the Washougal and Lewis Rivers. The first year of data were officially submitted to Ecology in November 2018.

This work was critical to facilitating planning approvals for the Phase 5 Projects.

Schedule

The Department of Ecology has submitted the Water Quality Assessment to Environmental Protection Agency for Clean Water Act approval.

Stay Up to Date

Throughout the Phase 5 Expansion, interested community members can follow progress by subscribing to our newsletter.

Contact Us

If you have any feedback or thoughts you want to share with us contact us using the information below.

For more information, contact:

Robin Krause, PE

Principal Engineer | Transmission & Treatment

Clark Regional Wastewater District